USTMA Members share the goal that all end-of-life tires enter sustainable and circular end-use markets.

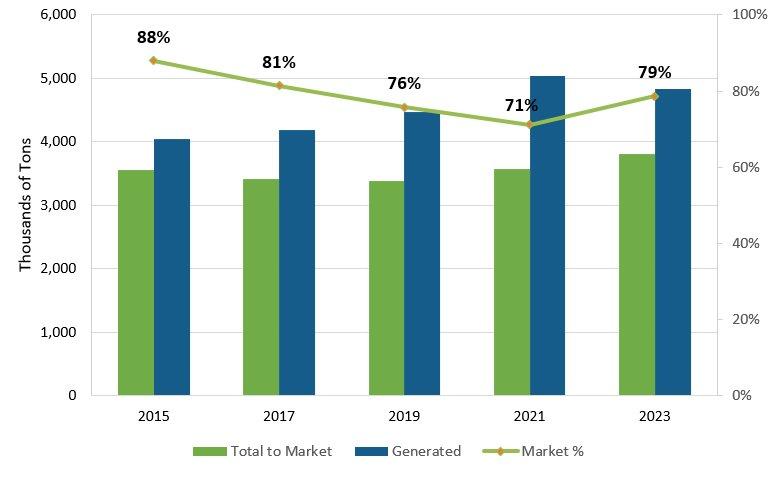

Tires are one of the most recycled products in the U.S. The management of end-of-life tires (ELT) has been a priority for USTMA members for almost three decades. USTMA works with stakeholders, including states, the U.S. EPA and the industry, to incentivize market development and advance federal and state regulations that foster sustainable tire recycling markets. According to the 2023 End-of-Life Tire Management Report, approximately 79% of ELTs currently go to tire recycling and reclamation markets.

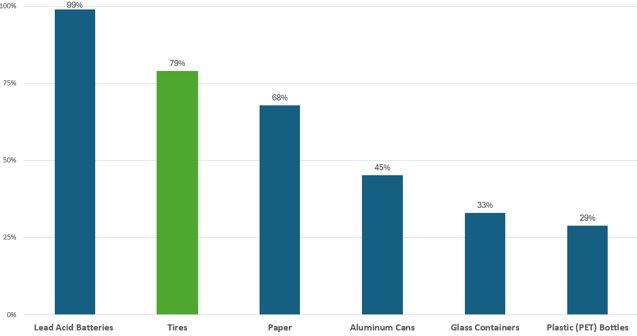

End Use Rates for Common Materials

Total MSW Recycling and Composting by Material

94 million tons

- Lead acid batteries: 99% (Battery Council International 2021)

- Tires: 79% (USTMA 2023)

- Paper: 67.9% recovery rate (AF&PA 2022)

- Aluminum cans: 59.7% (Aluminum Association 2021)

- Glass bottles: 31.3% (Glass Packaging Institute 2023)

Plastic (PET) bottles: 26.2% (NAPCOR 2022)

2023 End Use Rates for Common Materials

2023 End Use Rates for Common Materials

Building More Markets for End-of-Life Tires

USTMA is working with states and the federal government, industry groups, recyclers, researchers and environmental groups to grow new and existing markets, which require:

- Investment in ELT tire solutions that advance the circular economy.

- State grant programs to grow new and existing tire recycling markets.

- Federal investment in sustainable infrastructure advancement that advances innovation while protecting health, safety and the environment.

- Additional research to assess lifecycle impacts.

While the challenges are complex, our mission is simple: 100% of ELT tires enter sustainable and circular markets. Read more in our 2023 End-of-Life Tire Management Report.

Tire Recycling Markets

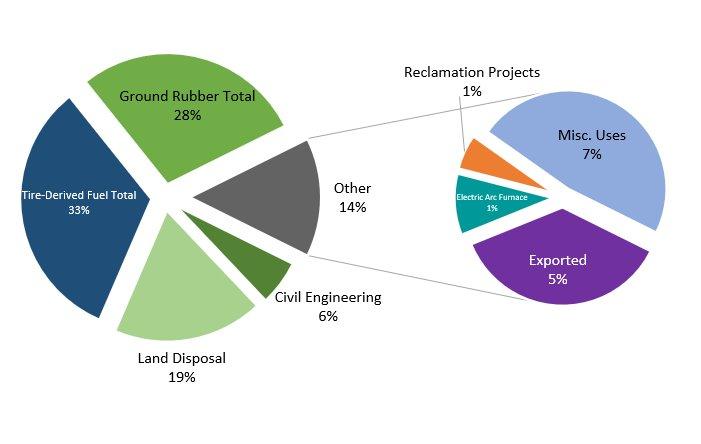

End-of-life tires are recycled into products such as rubber modified asphalt, automotive and other products, mulch for landscaping, tire-derived fuel and new applications like infiltration galleries that filter stormwater. USTMA recently funded research to advance the knowledge of rubber modified asphalt. The study found that rubber modified asphalt provides demonstrated economic, performance and environmental benefits. It provides cost savings over the life of the asphalt, extends pavement life and reduces noise, CO2 emissions and tire and road wear particles.

Our members also invest in tire recycling markets. Michelin, Bridgestone and Continental have partnered with pyrolysis companies to advance the use of recycled carbon black (rCB) to produce new tires. Michelin partnered with Scandinavian Enviro Systems to increase end-of-life tire recycling. Bridgestone joined with Delta-Energy Group to bring at-scale use of rCB to the tire market.

Reducing Remaining Stockpiles Through Proper Management

USTMA promotes end-of-life tires going to sustainable end-use markets because these tires in stockpiles create many dangers including fire and disease risk.

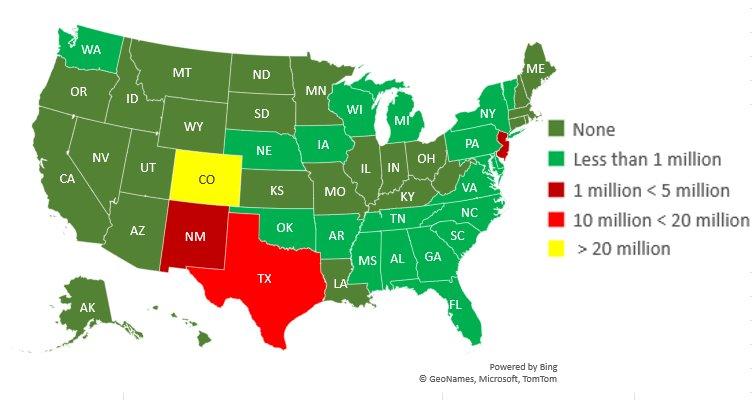

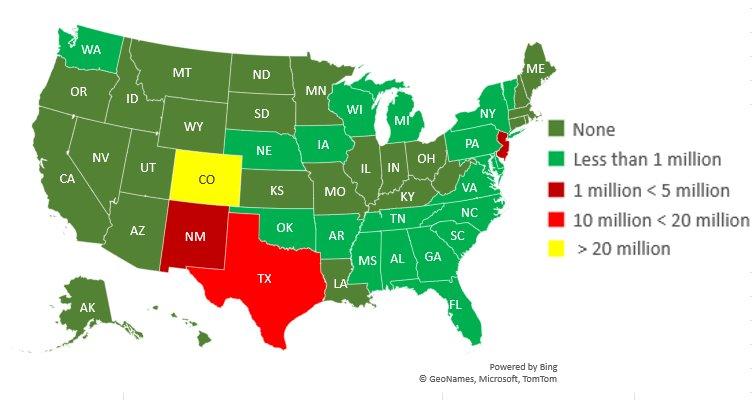

In 1990, the EPA estimated that more than 1 billion ELT tires were stored in illegal or abandoned stockpiles. By 2023, working in partnership with states, only about 48 million remained, an over 95% reduction. USTMA continues to work with states to abate the remaining stockpiles and prevent their reoccurrence.

Reducing Remaining Stockpiles Through Proper Management

Today, roughly 48 million end-of-life tires are contained in stockpiles, down from almost 1 billion in 1990. USTMA continues to work with state legislators and regulators on programs to help eliminate stockpiles.

The bulk of the remaining stockpiles are concentrated in six states:

- Colorado*

New Jersey

- New Mexico

Texas

*have ongoing abatement programs