Sign up for The Road to 100% Tire Circularity: ELTs Going Full Circle Webinar Series.

USTMA has urged Congress to designate rubber-modified asphalt (RMA) as a preferred material for federal road projects and to fund research on its benefits. Early findings show that RMA can reduce environmental impact. Additionally, RMA is cost-effective, extends pavement life, and reduces or delays maintenance, leading to significant savings when analyzed with life cycle cost techniques.

USTMA has called on Congress to fund research and demonstration projects using TDA in federal, state and local construction projects. TDA (large shreds of scrap tires) can be used as cost-effective infill material for roadside embankments, retaining walls and stormwater infiltration galleries. The use of TDA realizes significant benefits, including reducing costs compared to traditional mined construction materials and improved drainage in stormwater infiltration galleries. Studies show TDA use in infiltration galleries can also reduce metals loading in stormwater.

USTMA promotes domestic manufacturing and use of retreaded tires for commercial vehicles to enhance sustainability and grow American jobs. Commercial tire retreading provides a highly effective way to recycle tires with many additional notable economic and environmental benefits. In addition to job creation, retreading reduces energy consumption, CO2 emissions, raw material usage and tire disposal challenges. Congress has an opportunity to increase domestic retreaded tire demand by requiring use of these tires in the federal fleet.

Reducing Tire Stockpiles & Increasing Recycling Rates

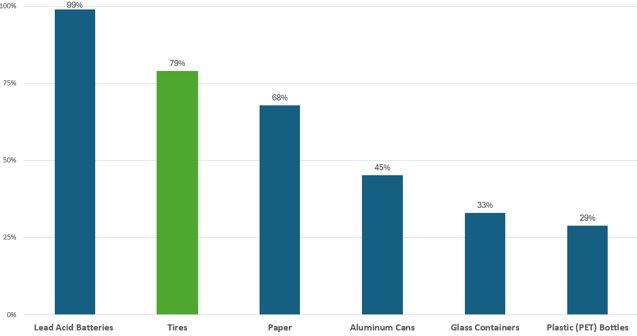

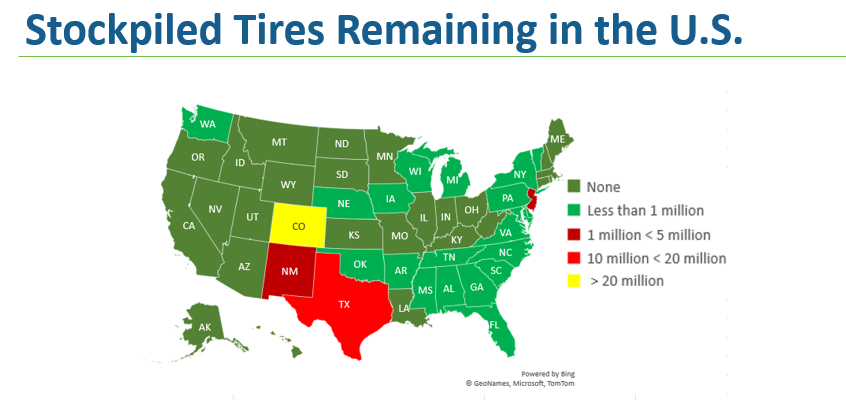

For decades, USTMA has promoted tire recycling legislation to prevent environmental issues from end-of-life tires. Its members support strong state programs to deter illegal dumping and reduce stockpiles and have prioritized managing ELT tires, which has reduced illegal and abandoned stockpiles from more than 1 billion in 1990 to less than 48 million nationwide in 2023—an over 95% reduction. The tire recycling rate has also increased from 11% in 1990 to 79% in 2023, making tires one of the most recycled products in the U.S.

USTMA works with stakeholders to expand sustainable tire recycling markets. Despite 79% of tires being recycled, the generation of end-of-life tires continues to outpace recycling, underscoring the need for further market development.

ELT to clean up in 1991

Tires to clean up in 2023

States with < 1M ELTs remaining