USTMA members share the goal that all end-of-life tires enter sustainable and circular, end-use markets

Tires are one of the most recycled and reclaimed products in the U.S. The management of end-of-life tires has been a priority for U.S. tire manufacturers for almost three decades. USTMA works with stakeholders, including states, the U.S. EPA and industry to incentivize market development and advance federal and state regulations that foster sustainable tire recycling markets.

USTMA 2023 End-of-Life Tire Management Report

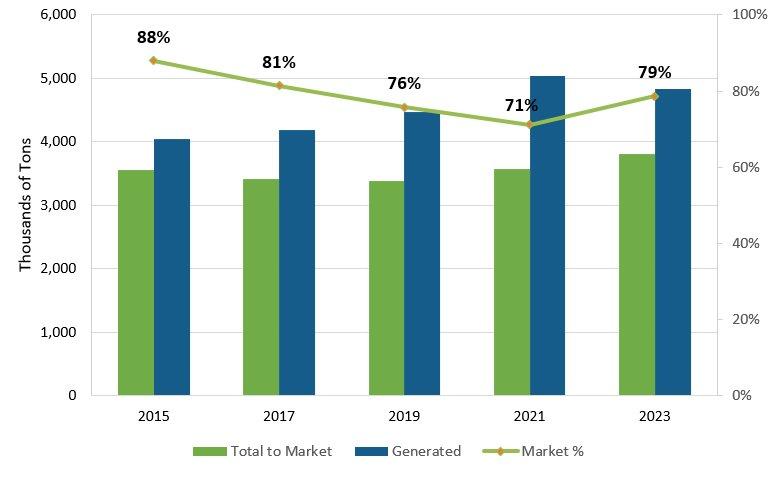

According to USTMA's 2023 End-of-Life Tire Management Report, tire recycling markets with annual generation, consuming approximately 79 percent of annually generated end-of-life tires in 2023, up from about 71 percent reported in 2021.

U.S. End-Of-Life Tire Market Trends 2015 - 2023

USTMA Tire Recycling Market Promotion

Each year, more than 250 million end-of-life tires (ELT) are generated in the U.S. While tires are among the most recycled and reclaimed products in the country, it's crucial to expand end-use markets to keep pace with the annual production of ELTs. This growth is essential to prevent stockpiles and illegal dumping of tires. USTMA sees the most market growth potential in rubber-modified asphalt and tire-derived aggregate, thanks to historic investments from the Bipartisan Infrastructure Law and the Inflation Reduction Act. We continue to advocate for increased investment and expansion in these areas, while also pushing for greater focus on domestic retreading of commercial tires.

USTMA has called on Congress to fund research and demonstration projects using TDA in federal, state and local construction projects. TDA (large shreds of scrap tires) can be used as cost-effective infill material for roadside embankments, retaining walls and stormwater infiltration galleries. The use of TDA realizes significant benefits, including reducing costs compared to traditional mined construction materials and improved drainage in stormwater infiltration galleries. Studies show TDA use in infiltration galleries can also reduce metals loading in stormwater.

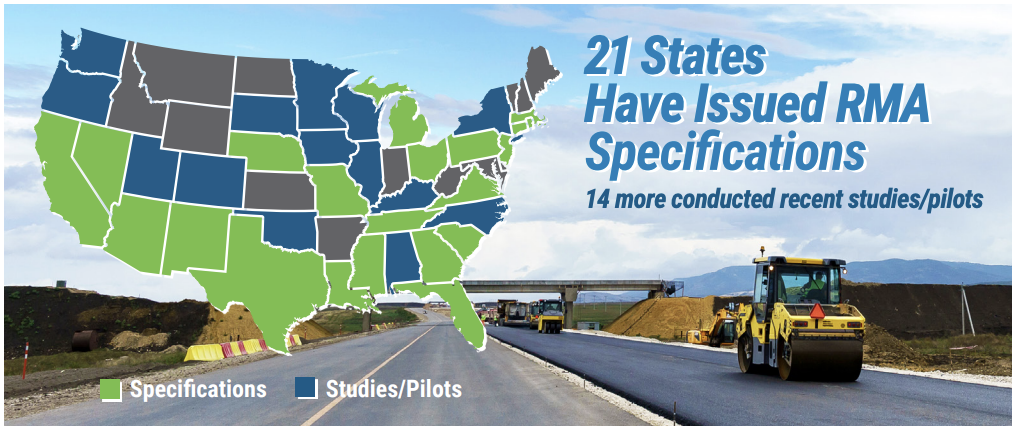

USTMA has urged Congress to designate rubber-modified asphalt (RMA) as a preferred material for federal road projects and to fund research on its benefits. Early findings show that RMA can reduce environmental impact. Additionally, RMA is cost-effective, extends pavement life, and reduces or delays maintenance, leading to significant savings when analyzed with life cycle cost techniques.

USTMA promotes domestic manufacturing and use of retreaded tires for commercial vehicles to enhance sustainability and grow American jobs. Commercial tire retreading provides a highly effective way to recycle tires with many additional notable economic and environmental benefits. In addition to job creation, retreading reduces energy consumption, CO2 emissions, raw material usage and tire disposal challenges. Congress has an opportunity to increase domestic retreaded tire demand by requiring use of these tires in the federal fleet.

USTMA Continued Advocacy in Tire Recycling

USTMA has collaborated with state and federal governments, industry organizations, recyclers, researchers and environmental groups to expand both new and existing markets. which require:

- Federal investment in sustainable infrastructure that advances innovation while protecting health, safety and the environment.

- Additional research to assess lifecycle impact

- Investment in tire recycling solutions that advance the circular economy.

- State grant programs to grow new and existing markets.

Rubber Modified Asphalt

- Summary of State Specifications for Rubber Modified Asphalt

- Rubber Modified Asphalt One Pager

- State of Knowledge Report on Rubber Modified Asphalt

- Rubber Modified Asphalt State of Knowledge Webinar Presentation (July 22, 2021)